PRODUCT INTRODUCTION

Cemented Carbides with Excellent Duability for Warm/Hot Forging Application

W Series

- Corrosion

Resistance - Impact

Resistance - Oxidation

Resistance - High Fracture

Toughness - Hot Forging

W Series excels in wear and oxidation resistance at high temperatures. Even when used under harsh high-temperature conditions, oxidative wear is less likely to occur, contributing the longevity of molds.

Properties

| Grades | Grades Classification Symbol | Specific Gravity |

Hardness (HRA) |

Transverse Rupture Strength (GPa) |

Fracture Toughness (MPa・m½) |

|---|---|---|---|---|---|

| WM38 | RU-80 | 12.70 | 77.5 | 2.2 | 30 |

※All data shown are typical values, not guaranteed values.

※We will not compensate any loss and damage caused by using all data.

※We reserve the right to modify the data due to technical progress.

Characteristics

-

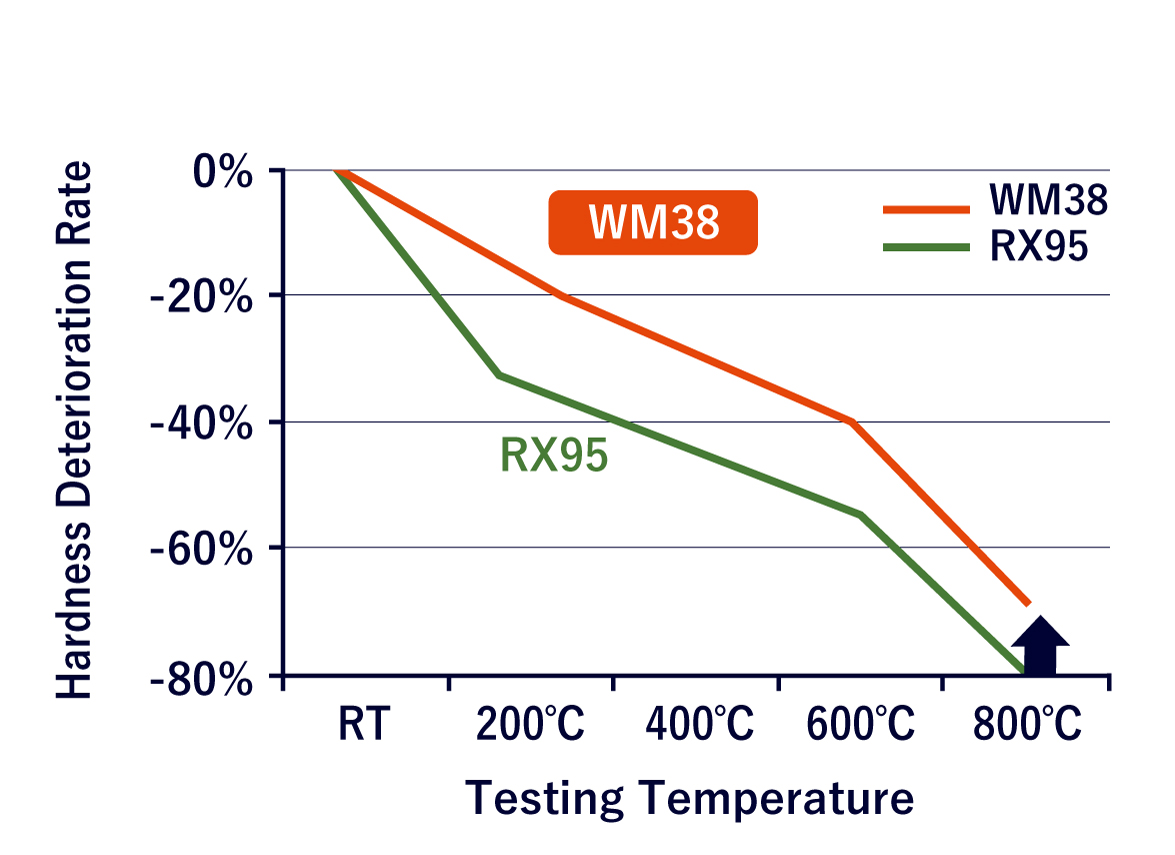

- Comparison of Hardness Deterioration Rate

- WM38's hardness deterioration rate at 800℃ is improved about 10% in comparison with RX95.

-

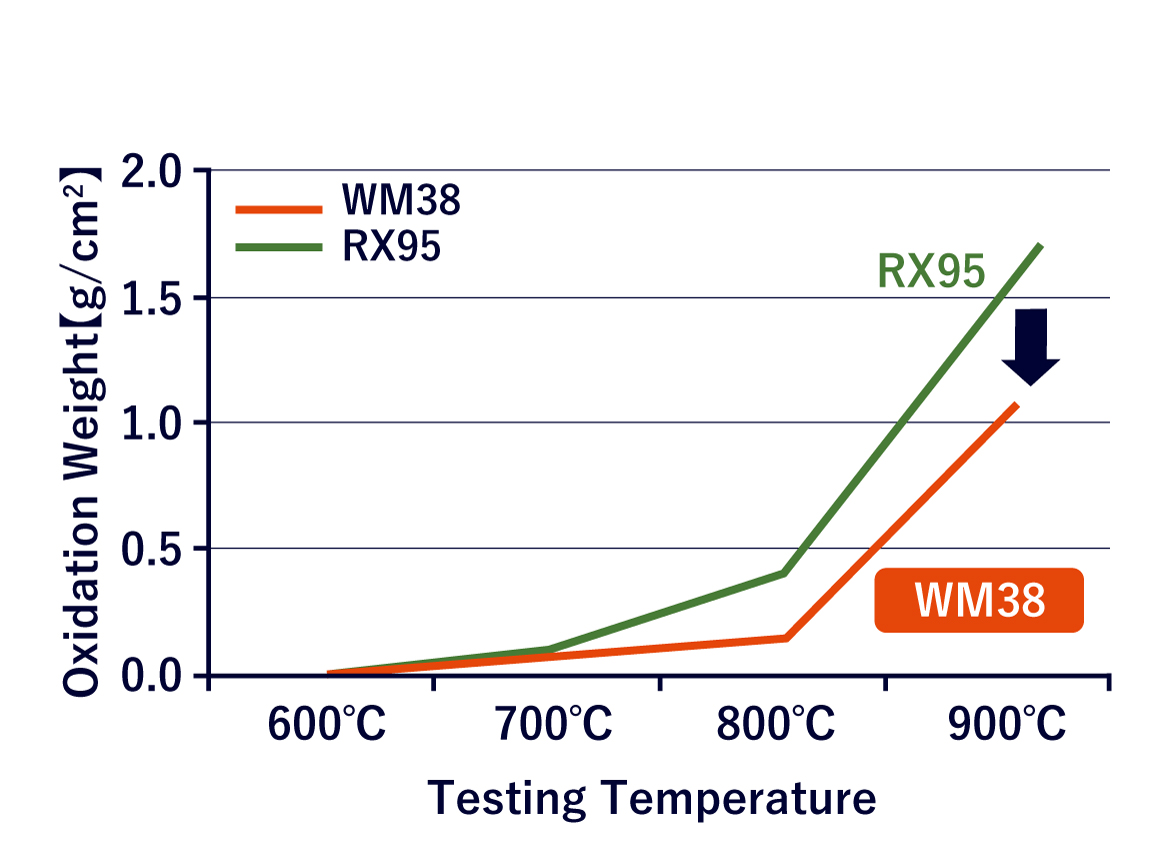

- Comparison of Oxidation Resistance

- WM38's oxidation weight at 900℃ is decreased about 40% in comparison with RX95.

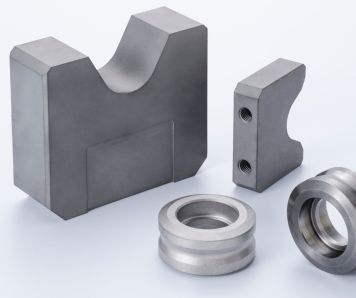

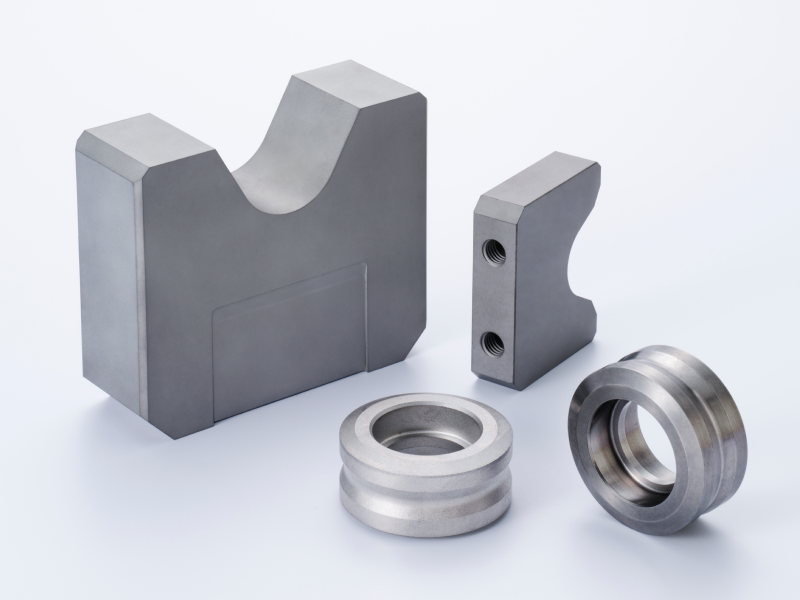

Typical Applications

- Dies

- Punches

- Die

- Rolls

- Moving Blades

- Fixed Blades