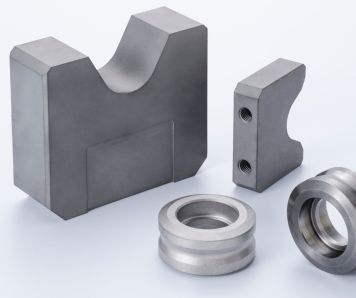

Manufacturing that is thorough in quality

Manufacturing Process

Quality control is maintained at every step, from material selection and mixing to forming, sintering, and shipping, following ISO 9001 standards. Cemented carbides are crafted at Sanalloy using state-of-the-art machining tools and sintering furnaces featuring pressurization treatment, facilitating the production of components for a wide array of industries. The increased production capacity allows for the provision of high-quality products with short lead times.

Inspection System

Reliability and safety are ensured through a rigorous quality inspection system, utilizing the latest analysis equipment for product inspections.

-

- 1Blending

- Determine raw materials (WC powder, Co powder and other powders) by composition ratio of each grade and the weight.

-

- 2Mixing

- Homogeneously mix and disperse various raw powders by using dispersing and mixing apparatus. Achieve activation of particle surface.

-

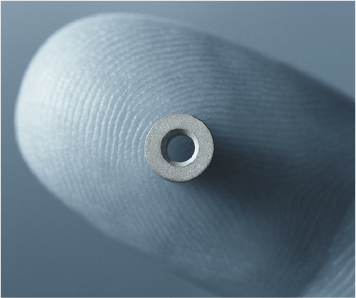

- 3Pressing

- Press the mixed and dispersed powder by molds and make compacted items as cylindrical and block shapes.

-

- 4Pre-Sintering

- Conduct heat treatment at 550~900℃ in order to obtain a strength capable of forming compacted items.

-

- 5Forming

- Formed items will have 20% shrinkage in sintering process. Therefore, we form into the shapes according to customers’ request in anticipation of this shrinkage.

-

- 6Sintering

- Put formed items into sintering furnace. Conduct liquid phase sintering at 1300~1500℃.

-

- 7HIP

- Conduct heat treatment by using Argon gas as pressure-transmitting medium. Remove prove remaining inside of carbides.

-

- 8Production Inspection

- Conduct products appearance and shape inspection, quantity confirmation.

-

- 9Packing and Shipping

- Deliver the acceptable products to customers after packing with eco-friendly packaging materials.